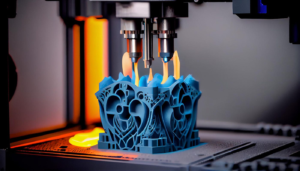

3D printing is a new technology that allows users to create physical objects by bonding layers of print material one at a time. It is a popular technique for prototyping and creating lightweight geometric objects.

Once your design is complete, you must convert it into a format your printer can read. This process is called “slicing.” The slicing software will convert the STL file into Xcode, which contains precise instructions for your printer. Click here to Learn More.

3D printing is a manufacturing process that builds up objects layer by layer instead of casting or molding them in a single step (consolidation) or cutting and machining them out of solid blocks (a subtractive process). This new technology eliminates many costs associated with traditional fabrication methods, including the need for expensive tooling and machinery. It also allows companies to produce smaller quantities of products more quickly. This positively impacts the environment, as it reduces waste and energy use. In addition, it brings production closer to the consumer, thereby reducing transportation costs and lowering the amount of carbon that is poured into the atmosphere.

The technology was first developed in the 1980s and has since evolved into a powerful business tool. Its origins are in rapid prototyping, where engineers used it to accelerate the development of new products by allowing them to quickly produce prototypes. Today, it’s often used for low-volume or custom manufacturing. Car manufacturers, for example, print spare parts, tools and jigs to improve their design and manufacturing processes. They can also produce end-use parts, which lowers stock levels and shortens product development cycles.

A key benefit of this technology is its ability to create a variety of geometries. Traditional manufacturing methods have limited designs, whereas 3D printing offers a wider range of options. For example, PepsiCo printed several different sizes of its Ruffles chips and tested them with consumers to determine which size was more popular.

Moreover, the technology is becoming more affordable and accessible for businesses. This is due to advances in materials science, which have enabled a wide range of printers to become more powerful and cost-efficient. The ability to print multiple materials, which can be used together to make complex shapes, is another important advancement in the technology. As a result, it’s now possible to build structures with unprecedented strength and durability using additive manufacturing. This is an exciting development for the industry, as it will allow companies to develop lightweight, durable components for their vehicles and aircrafts.

It’s cheaper

As an additive manufacturing process, 3D printing costs less than traditional processes. The cost of materials, machinery and labor are all significantly lower, allowing companies to save on overhead and production costs. In addition, fewer parts are required to produce a finished product, which reduces inventory costs and storage space. 3D printing also reduces the time it takes to manufacture a new product from conception to completion. Traditional manufacturing processes require a tooling stage before the products can be produced, which adds to production costs and increases lead times. Additionally, traditional manufacturing requires large amounts of warehousing and storage to hold spare parts for future use. However, 3D printing allows you to print spare parts on demand, reducing warehousing and storage costs.

Another advantage of 3D printing is that it produces far fewer waste products than traditional fabrication methods. This reduces the need for expensive landfills and minimizes the environmental impact of shipping discarded components to other countries for processing. Additionally, the technology is becoming more accessible and affordable, allowing even small businesses to benefit from its advantages.

The democratization of 3D printers has opened up a world of possibilities. For example, the technology can be used to create customized medical devices and consumer products that are molded to the user’s unique anatomy. This can have life-saving implications in the case of heart implants or prosthetics. It can also be used to create personalized medicine and targeted drug delivery systems. In addition, it can be used to construct artificial tissues and organs for transplantation.

As a result, it has become easier for manufacturers to bring their products to market and compete with global competitors. It has also enabled companies to develop more innovative products and improve existing ones by incorporating 3D-printed parts. This has the potential to revolutionize the way we live, work, and play. For instance, it could make it possible for individuals to have their own prosthetic legs that are custom-made for them, instead of having to wait months for a factory in China to produce them. This would not only reduce costs but also increase speed to market.

It’s faster

3D printing is faster than traditional methods of manufacturing, which require the creation of molds and other tooling. Additionally, it can produce a prototype in a matter of days or even less. This speed-up can drastically reduce the product development cycle, saving time and money for companies. It can also help them to improve their design and engineering processes, which will lead to higher-quality products.

However, the print time varies depending on a number of factors, such as layer height and resolution. Thicker layers, which are often required for high-quality prints, can accelerate the process by reducing the amount of material used and allowing the printer to complete the job in fewer passes. In contrast, thinner layers increase resolution and surface finish but may slow down the process.

This flexibility in the production process is one of the major reasons why 3D printing is gaining popularity. It allows manufacturers to produce small batches of parts on demand, which can greatly reduce inventory costs and warehousing expenses. It also helps to keep production in-house, which can protect intellectual property and maintain confidentiality.

Furthermore, the digital nature of 3D printing offers a greater degree of control over the quality of outputs. For instance, it allows designers to identify and correct potential problems during the modeling phase, thereby producing better-quality prototypes. This digital validation also ensures that a final product is free from defects and will function as intended.

Finally, the ability to manufacture on-demand enables businesses to respond quickly to customer needs. This shift in production can significantly lower inventory costs and shipping expenses, while reducing waste. Moreover, it can also decrease storage and warehousing costs by eliminating the need for vast warehouses.

The versatility of this technology enables engineers to push the boundaries of what can be made. For instance, it’s possible to create highly complex shapes that are impossible to fabricate using other technologies. This freedom also paves the way for new designs and products, which can benefit many industries.

In addition, 3D printing can be used to create custom prosthetics and medical implants, enabling people with physical disabilities to feel more connected to their environment. It can also be used to make jewelry, toys, and other accessories that allow children with disabilities to express themselves.

It’s more environmentally friendly

In addition to being cheaper, 3d printing is also more environmentally friendly than traditional manufacturing methods. This is due to the fact that it uses less energy and produces fewer harmful emissions. It also allows for a higher degree of customization and reduces the need to waste materials. For example, a product can be printed with just the necessary materials for its intended use. This eliminates the need for multiple components such as a metal base and insulation. It also cuts down on the amount of plastic used, which is a major contributor to landfills.

There are several different materials that can be used in 3d printing, including polymer plastics, bioplastic, concrete, and metal. The most common plastic is thermoplastic polymer, which is a durable and versatile material that can be printed with various colors and textures. However, it is not biodegradable and requires virgin petrochemicals to create. Fortunately, eco-friendly 3d printing resins are on the rise, which help to minimize the environmental impact of this technology. These resins are made from recycled materials and biodegradable substances, such as corn starch and sugar cane.

Another benefit of using 3D printers is that they can be used to create products locally, which cuts down on transportation and shipping emissions. This is particularly important when dealing with large, bulky items such as houses. According to All3DP, one company recently partnered with Habitat for Humanity to print a single-level concrete home. It took just 12 hours to build, which is a huge improvement over the traditional building process that typically takes weeks.

Moreover, it’s possible to create multiple items at the same time using a 3D printer. This eliminates the need to store products until they can be sold, which can save space and energy. 3D printers can also produce items on demand, which can drastically cut down on shipping expenses and waste.

However, it’s important to note that 3D printing is not without its downsides. For example, some machines emit volatile organic compounds (VOCs), which are harmful to the environment. The level of VOCs depends on the filament material, printer model, temperature settings, and printing speed.